LOG iN – eKANBAN

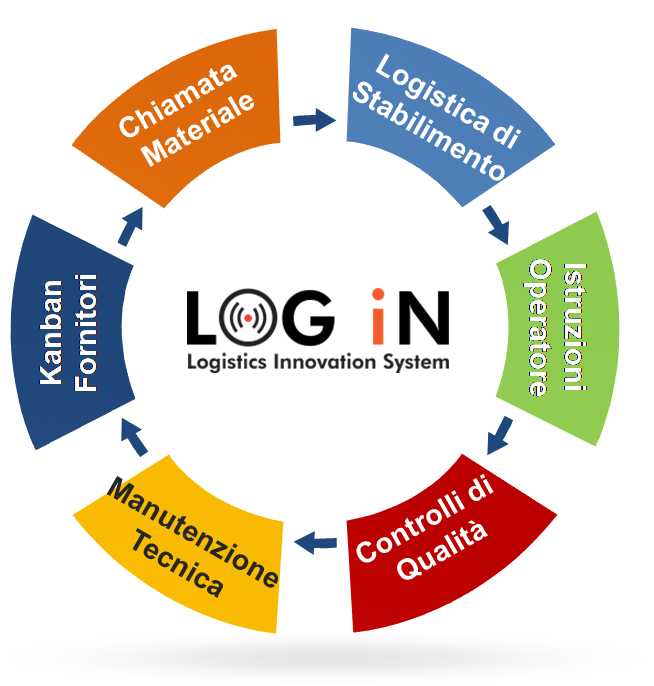

Efficiency of plant logistics by automating the process in PULL logic with the only platform available to date, designed and engineered for the management and optimization of the production line.

LOG iN – eKANBAN platform is an intelligent system for managing and assigning missions able to standardize logistics activities and guarantee maximum production flexibility with a reduction in indirect costs of 25% and resource saturation of over 90%.

Advantages

Features

New technologies

Radio buttons

Auto-powered radio buttons for the components call with no need of cabling (free installation along the line)

Tablets e Touch Screens

Components call via touch with status visibility of the calls. Possibility to integrate textual or animated operative instructions

Digital Signage

Visibility of the component call and status of the calls in progress via Digital Signage (Monitor)

Standard Terminals

Use of the standard mobile terminals already available to the logistic operators

Smart Badges

Integrate production and logistics in real time using the most suitable innovative devices (Smart Badges) for line supervisors/operators

Totem along the line

Access to the critical tasks (change in production, delays, exceptions, etc.) through the PC Totem positioned along the line for the highest level of efficiencyFunctions and features

LOG iN News

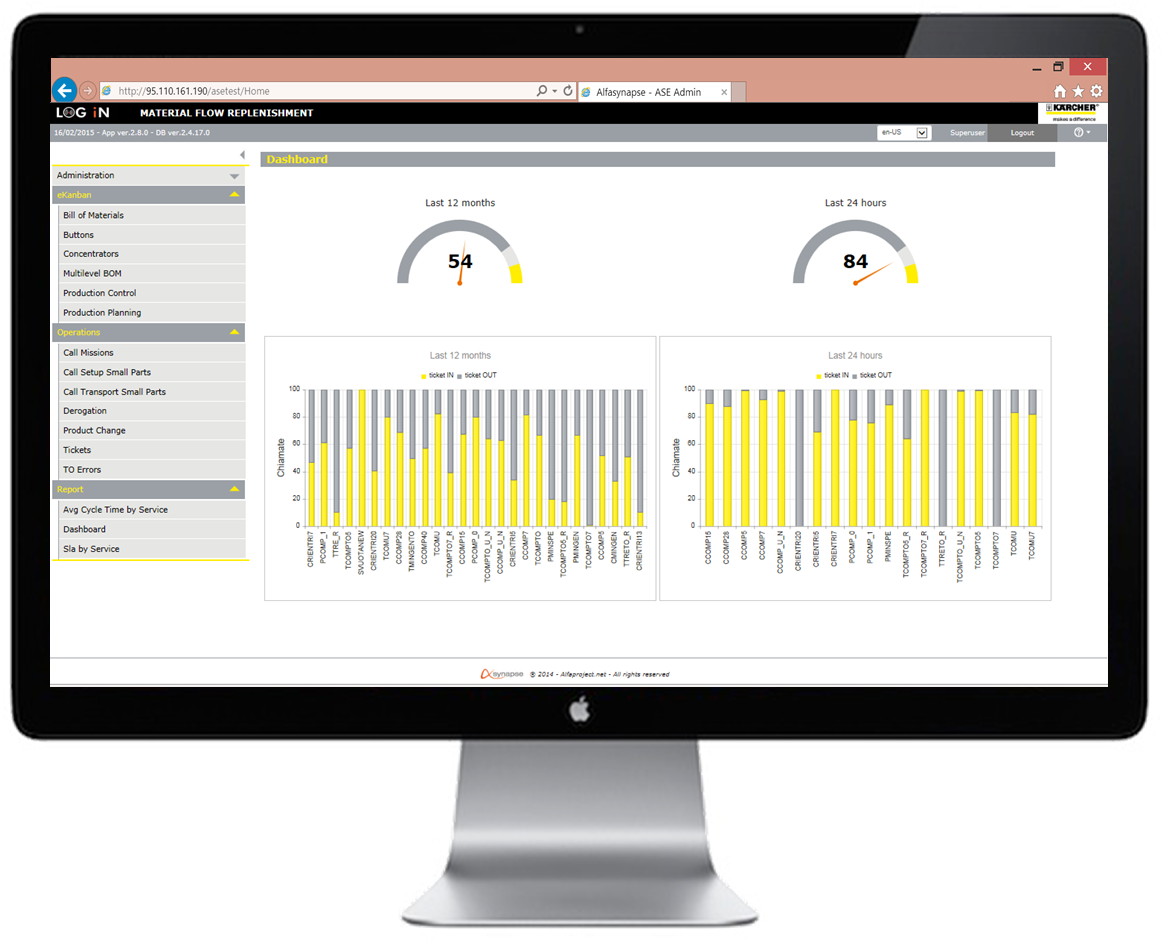

Successful cases

Efficiency of factory logistics. The Kaercher plant in Quistello (MN), one of the largest Kaercher plants in the world, through the implementation of the LOG iN – eKanban platform, optimizes the interlocking processes of the 15 production lines and enables the PULL model.

LOG iN – eKanban allowed to:

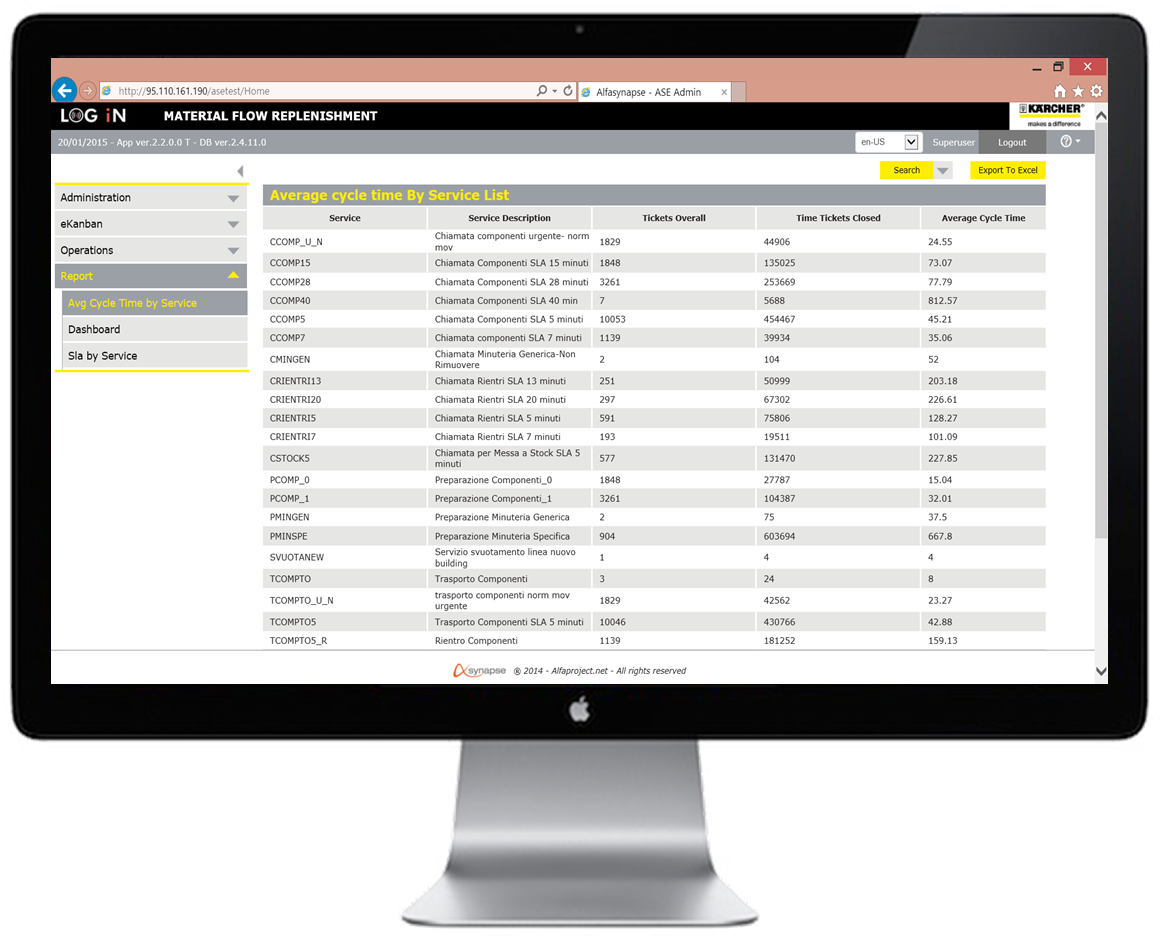

— Delete the dedicated logistics operator

– Significantly reduce logistics hours

– Transforming indirect costs into direct production costs