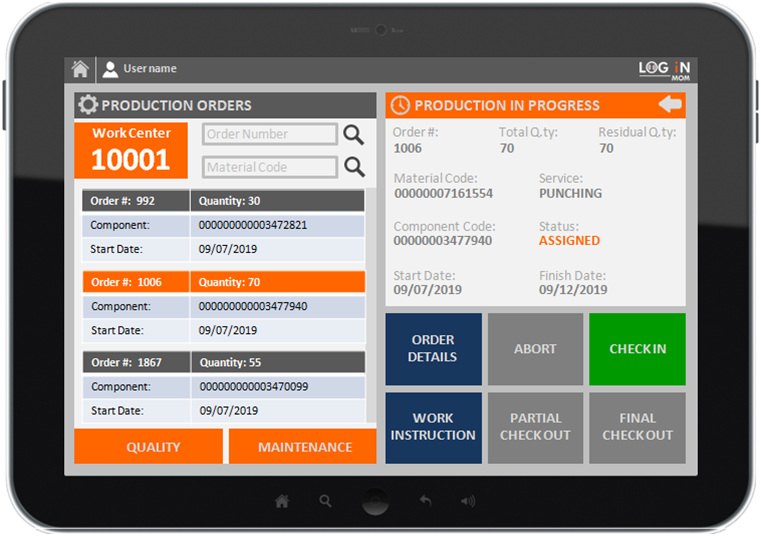

LOG iN – MOM

The first “Made in Italy” Manufacturing Operations Management System to support the digital integration of resources, processes and machinery for a “in-throw” and efficient production.

The LOG iN – MOM platform allows to improve the efficiency of production processes by integrating the management and traceability of production and logistics and maintenance activities in a single tool.

LOG iN – MOM enables a digital industrial model that allows automating, standardizing and making processes more efficient, making production faster and more accurate.

Advantages

- Implementation of PULL model

- Dynamic management of production priorities

- Advances in real time

- Reduction of crossing times

- Traceability of the single product / container

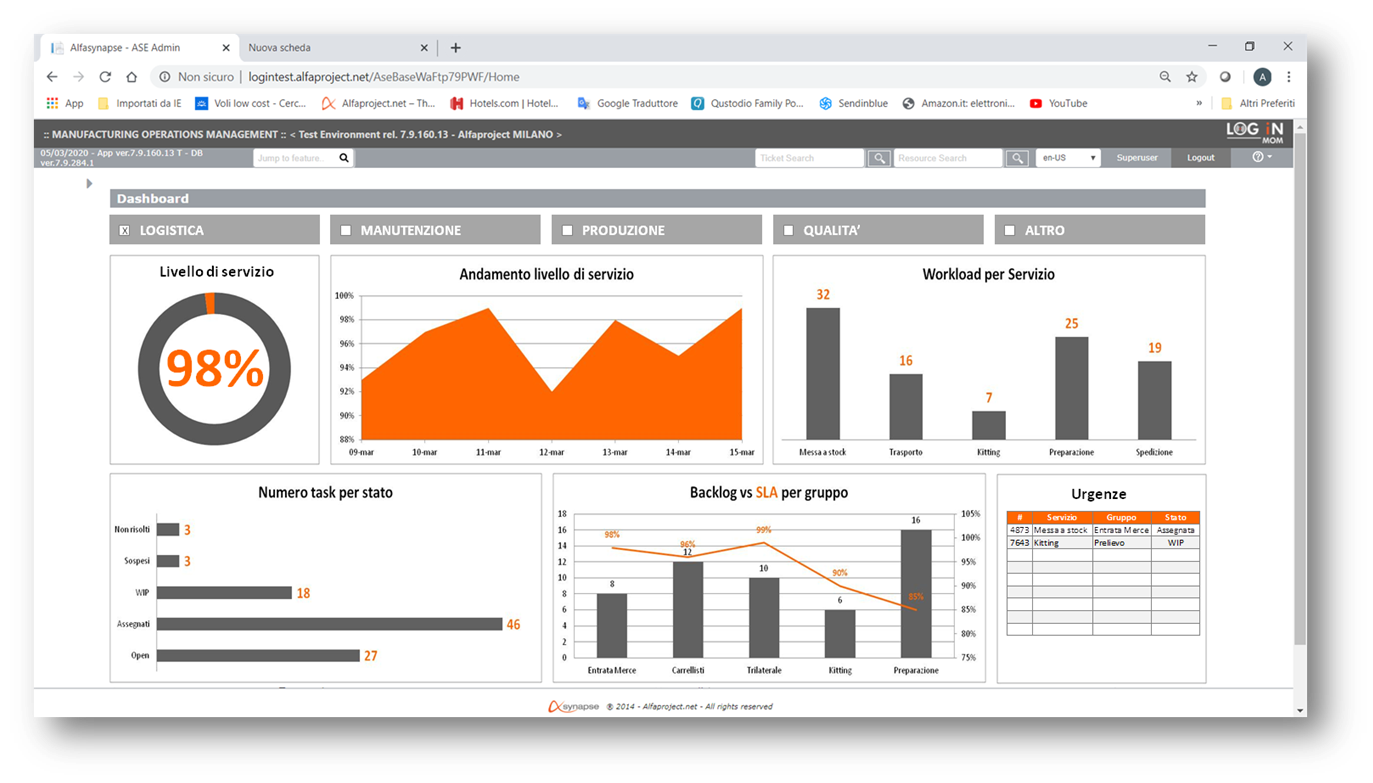

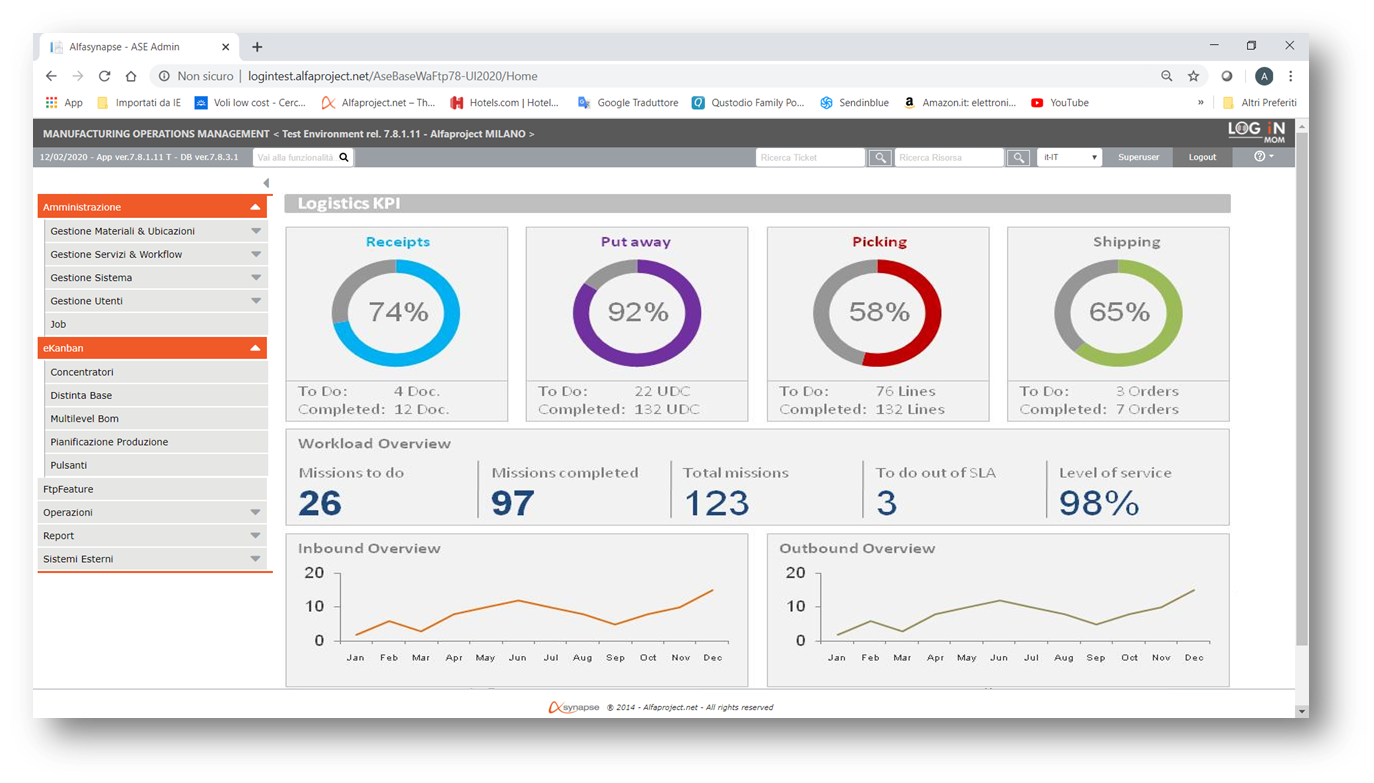

- Tracking and real-time monitoring of production activities

- Integration with logistics processes

- Monitoring and measurement of tail times

- Breakdown of indirect costs

Governance

Expertise areas

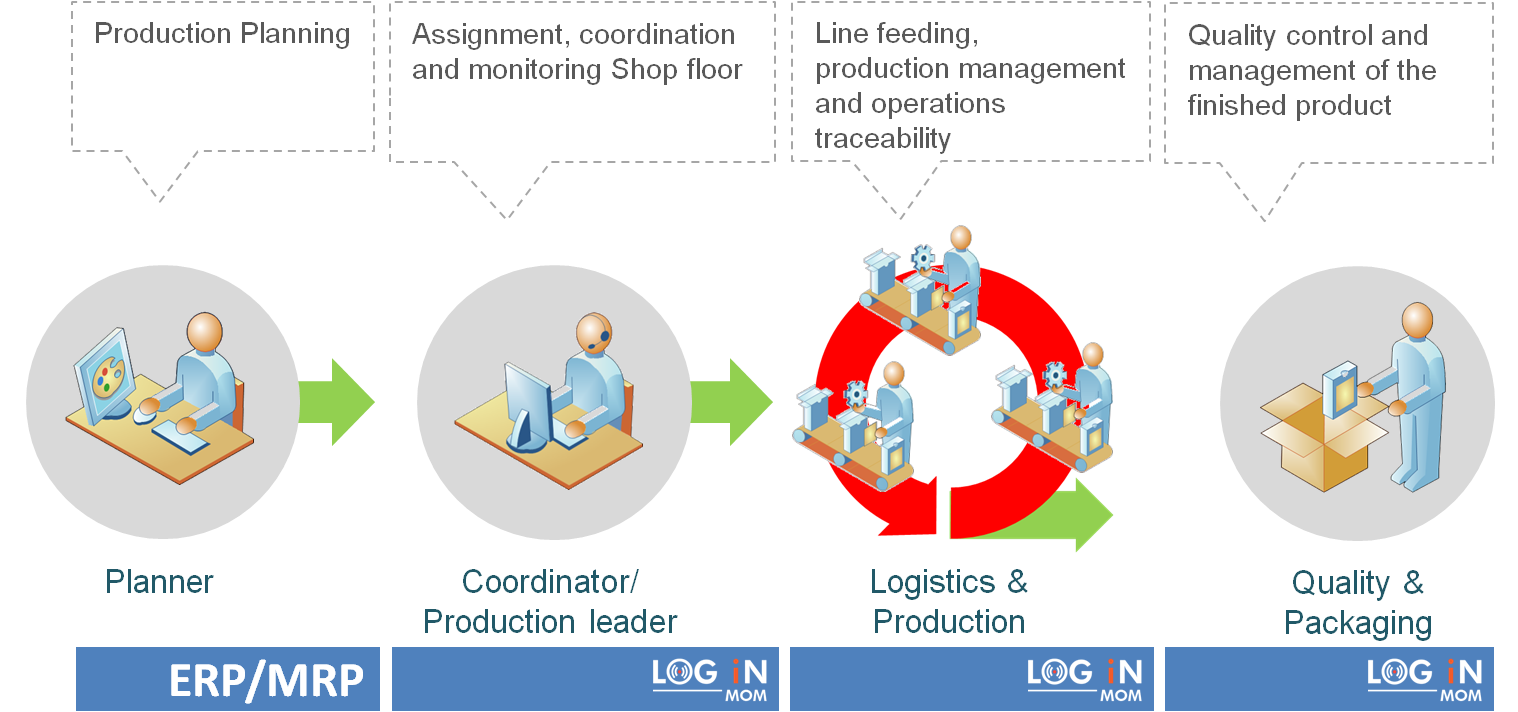

Production Workflow

From the production cycle present in the ERP system, LOG iN – MOM dynamically creates the entire production workflow by integrating the accessory phases not present in the cycle (logistic transport, any quality controls, etc.).

Dynamic priorities

Automated and dynamic management of the priorities of every single production process phase, based on the delivery time of the finished product. Stress, warning and raising of priorities become automatic.

Integrated logistics

Automatic logistic engagement for picking the components necessary for the production and / or transport of semi-finished products from one work center to another one, giving the operator all the needed information to well perform the activity.

Proactive management

Knowing the necessary processing steps and the crossing times, the system proactively manages the activities and optimizes them so as not to delay the expected delivery times.

Digitization of the workplace

Implementation model